THE HISTORY SECTION WILL RECORD THE HISTORY OF KILLAMARSH WHICH IS RICH AND DIVERSE.

The sections we have included so far are:

1. The Village of Killamarsh

2. Industry

3. The History of Rail in Killamarsh

4. Killamarsh Forge

5. The History of Mining in Killamarsh

Westthorpe Colliery

High Moor Colliery

Norwood Colliery

The Miners’ Holiday Camps in Skegness and Rhyl

6. Killamarsh Churches

7. Killamarsh Schools

8. The Flour Mill

9. The Skating Tragedy in Killamarsh

10. Rother Valley Country Park

11. Inns, Pubs and Beerhouses

12. Killamarsh Shops

13. Booth and Fisher Buses

If you have any more information you can add to any subject in the History section, or if you have any relevant photographs we can loan and copy, please email secretary@killamarsh.org or telephone 0114 2484812

_________________________________________________________

THE VILLAGE OF KILLAMARSH

Killamarsh was mentioned in the Domesday Book with the name Chinewoldemaresc.

There are a number of smaller communities within the village – Norwood, Nethergreen, Westthorpe and Upperthorpe surround the village centre.

The following is an extract from Kelly’s Directory of the Counties of Derby, Notts, Leicester and Rutland. Published in May 1891.

KILLAMARSH, called in Domesday “Chinewaldmarese,” is a widely-scattered parish on the borders of Yorkshire, with a station on the Midland railway, 9 miles north-east from Chesterfield, 8 south-east from Sheffield and 162½ from London, in the North Eastern division of the county, Scarsdale hundred, Chesterfield union and county court district, Eckington petty sessional division, rural deanery of Staveley, archdeaconry of Derby and diocese of Southwell; the Chesterfield canal takes a circuitous route through the village. The church of St. Giles, standing in the centre of the parish, is a building of stone in the Norman, Perpendicular and Tudor styles, consisting of chancel, nave, south porch, vestry and an embattled western tower, with pinnacles and containing 6 bells: the chancel was rebuilt in 1845 at a cost of £600, and the church was further restored in 1877 at a cost also of £600, when the nave and porch were re-roofed, the old pews removed and open benches substituted: the east window is stained: the porch contains a fine Norman arch; and there are 250 sittings. The register dates from the year 1638, and is in good condition. The living is a rectory, average tithe rent-charge £168, net yearly value £323, including 110 acres of glebe, with residence, in the gift of the Crown, and held since 1887 by the Rev. Francis James Metcalfe. A mission room (iron) was erected in 1890. There are Congregational and Primitive Methodist chapels. Hewitt’s charity of £52 yearly, derived from 21 acres, is for bread ; the other charities for distribution amount to £20 yearly. Here are collieries, a steel forge and chemical works. Reginald Walkelyne Chandos-Pole esq. J.P. of Radburne Hall, who is lord of the manor, and Sir George Reresby Sitwell bart. of Renishaw Hall, are the chief landowners. The soil is heavy ; subsoil, clay. The chief crops are wheat, barley, oats, turnips, hay &c. The acreage is 1,659; rateable value, £11,515 ; the population in 1871 was 1,884, and in 1881 was 3,841.

Parish Clerk, John Batty.

POST & M. O. O., S. B. & Annuity & Insurance Office.- Samuel Cox, sub-postmaster. Letters arrive from Chesterfield at 7.7 a.m.; dispatched at 7-30 p.m: Sundays, arrive at 8.34 a.m; dispatched at 3.40 p.m. The nearest telegraph office is at Eckington

SCHOOLS:-

Endowed (mixed), erected in 1873 & enlarged 1876, & endowed with £40 yearly, for 208 children; average attendance 184. Frederick Hanson Fisher, master;

A School Board of 5 members was formed March 2, 1877; Thomas Webster, clerk to school board; Horatio Hardy, attendance officer

Board (mixed & infants), erected in 1819, for 160 boys, l60 girls & 200 infants; average attendance, 156 boys, 140 girls & 123 infants ; George Gilbert Watts, master ; Mrs. Matilda Watts, mist.; Miss Elizabeth Mills, infants mist

RAILWAY STATI0N – Josiah Farndon, station master

CARRIER TO SHEFFIELD.-William Hardy, Tues. & Sat

PRIVATE RESIDENTS.

Alderson Christr. Wm. Nether Green House

Barron Rev. W. R. [Cong.], The Manse

Dent Robert Angle, Shepcote Grange

Green Robert, Dale House

Metcalfe Rev. Fras. Jas. T.A.X.C.L. Rectory

Platts Robert, Norwood

Richardson Thomas Geo, Plantation House

Richardson Thos. Griffiths, Mansion House

Shadwick John

Simmonite John, Gannow House

Slagg Henry, Upperthorpe

Smith Miss Fanny, Netherthorpe

Soar Levi, Mount View House

Tankard John William, Norwood Villa

Walker Richard Wilfred, Nether Green

COMMERCIAL.

Bailey Edgar, grocer

Bartholomew Edward, farmer

Batty Joseph, grocer, Church Lane

Batty Sarah (Mrs.), shopkeeper. Nethermoor

Baumforth Chas. grocer, draper & beer ret

Bescoby William, shopkeeper

Boaler Samuel, shopkeeper

Bramhall Chas. beer retailer, High Moor

Carr Henry, blacksmith

Carr John, farmer

Carr William, grocer & provision dealer

Clark Duncan, surgeon

Cox Sl. shopkeeper. & news agent, Post Office

Deane Chas. shopkr. & marine store dlr

Derbyshire Chemical Co. Limited, tar distillers

Ellis Jether, Navigation Hotel

Ellor Esther (Mrs.), shopkeeper

Fairburn William, butcher

Fitton Dyson, draper, Shepcote Hill

Gleadall Agnes (Mrs.), Crown Inn

Glossop Peter, farmer, High Moor

Godber William, farmer

Greaves Fanny (Mrs.), shopkeeper

Green Herbert, grocer

Greensmith John, shopkpr. High Moor

Hall Charles, farmer

Hall Henry, farmer, West Thorpe

Hall John, butcher & farmer

Hardy Wm. Horatio, market gardener & carrier

Harris Charles, shopkeeper

Harris William, shopkeeper. & beer retlr

Highfield Edward, draper, clothier & dyers’ agent

Hodgson George M. farmer

Hutchinson Robert, farmer, High Moor

Johnson William, shopkeeper

Kelk George, hair dresser

Leah George, farmer

Leah Mark, farmer & fruiterer

Mallinder Charles, shopkeeper

Mallinder Frederick, farmer

Mallinder George, farmer

Mallinder John. Jun. hay & straw dealer, Upperthorpe

Mallinder Mary (Mrs.). farmer

Marrison Charles, tailor

Marshall William, draper

Martin Henry, pork butcher

Mattison & Sons, boot & shoe dealers

Milner George, beer retailer

Newton Edward, farmer

Newton Harriet (Mrs.), lamp & oil dlr

Nicholls Edmund, farmer, Old Hall

Norwood Chemical Works (John William Tankard, manager)

Parker John, shopkeeper

Platts Robert, M.B.C.V.S.L. veterinary surgeon, Norwood

Puttrell Charles, joiner & painter

Read Charles, farmer, Moot House

Richardson Thos. Griffiths, steel wire mfr

Rose Elizabeth (Mrs.), Nag’s Head P.H. & farmer & wheelwright

Rowbotham John, shoe maker. & beer retlr

Rowley Andrew, boot & shoe maker

Rudman George, shopkeeper

Sheepbridge Coal &: Iron Co. Limited (John William Tankard, manager), Norwood

Shepherd Albert, shopkeeper

Silver Walter, cowkeeper, High Moor

Simmonite Henry, Angel P.H. & farmer, Norwood

Simmonite John, farmer, Gannow House

Smith Job, Blacksmiths’ Arms P.H

Smith William, Midland Hotel

Snowden George, shopkeeper

Spencer Thomas, farmer

Stenton Joseph, stone mason & builder

Thorpe Thomas, butcher

Turton John, farmer

Wagstaff Clarence, butcher

Walker Charles, carter, High Moor

Walker George, farmer

Walker Richard Wilfred, druggist

Wardley George, farmer

Watson Sarah (Mrs.), farmer

Webster James, butcher

Webster Thomas, shopkeeper, collector of rates & clerk to school board

Whitfield Ann (Mrs.), beer ret. & farmer

Whiting George, grocer & provision dlr

Wilks Mary (Mrs.), shopkeeper. High Moor

Wilson Geo. picture framer & furniture dlr

Wood George, butcher

Woodward Herbert, farmer

Woodward John, watch maker & shopkeeper

_________________________________________________________

INDUSTRY

The community originally grew from a farming community, self sufficient in agricultural and dairy produce since the Middle Ages. In the 19th and 20th centuries, Killamarsh became a thriving mining village as the Sheffield steel industry demanded coal and transport links with Sheffield matured.

Coal has been mined in Killamarsh since at least the 15th century, but the first major mining operation opened at Norwood resulting in the population of Killamarsh almost doubling between 1861 and 1871.

Westthorpe and High Moor pits, which were the last two remaining, are now gone and were casualties of the early 1980s pit closure programme.

The River Rother which skirts the side of Killamarsh provided power to grain mills from the earliest times and was used by ironmongers and smiths from the late 18th century. Killamarsh Forge drew the special wire used in the core of the 2nd trans-Atlantic telegraph cable laid by the SS Great Eastern in 1866 as well as other equipment used in the splicing operations.

There is an industrial estate located in the Norwood area and light industrial units and a business innovation centre on the old Westthorpe Colliery site. To the west of the village is a small animal feed mill, and Ross and Catherall, a specialist alloys supplier to the aerospace industry.

_________________________________________________________

THE HISTORY OF RAIL IN KILLAMARSH

Many Killamarsh residents will not be aware that Killamarsh had three railway stations. Upperthorpe and Killamarsh opened on the 1st October 1898 and freight traffic could be worked from Langwith Junction to Sheffield without running over the Midland railway. A passenger service started on 30th May 1900.

The station remained open until 11th September 1939 when the passenger service was withdrawn. The railway cottages once occupied by the Station Master and staff are still there, with the loverbridge now leading to the path that runs parallel to the houses on the ‘Wimpy Estate’ leading and to the houses on Bryony Close.

The track bed can still be seen but nature has now reclaimed the railway.

Killamarsh West Railway Station

The original station was opened on 6 April 1841 by the North Midland Railway between Chesterfield and Masborough, on what became known as the ‘old road’. It was closed on 2 January 1843 by George Hudson during a period of financial difficulty.

A new station was built by the Midland Railway which opened on 21 January 1873. Although locally it was known as Killamarsh Midland, it would seem that the name was not officially adopted but on 25 September 1950 it was renamed Killamarsh West by British Railways.

The station was of typical Midland design, brick built and timber with a foot crossing between the platforms.

The station closed to passengers on 1 February 1954 and the line itself in July of that year. It remains in use as a freight route and some passenger trains are occasionally diverted this way. The line is now part of the current Midland Main Line.

Killamarsh Central Railway Station

The station was opened on 1 June 1892 on the west side of Station Road. The company on opening was the Manchester, Sheffield and Lincolnshire Railway. It was one of three station in Killamarsh, and is the only surviving example of a timber (MS & L) railway building left, of a type used on the northern section of the Great Central.

In 1890 the Manchester, Sheffield and Lincolnshire Railway Company under the general managership of Edward Watkin started work on the ‘Derbyshire Lines’ extension south of Beighton, then the most southerly part of the MS & L lines, with the aim of joining up with the Metropolitan Lines coming out of London, via the coalfields of North Nottinghamshire. This line would create extra traffic for the rest of the MS & L network to Manchester, Sheffield, Leeds and the Lincolnshire ports. The first stage of this project was the line through Killamarsh to Chesterfield and Heath.

In 1893 Parliament granted approval for the rest of the line south to London. The 92 mile route was started in 1895 and in August 1897 the company changed its name to the Great Central Railway. This route south became known as the ‘London Extension; and was the last main line to be built until the Channel Tunnel Rail Link in 2003.

The maximum gradient on the line was 1 in 128 and used only gradual curves, thus ensuring fast and smooth running. The first level crossing on the line when travelling north out of London was at Beighton near Sheffield, and the line was built to what is now called ‘Continental Loading Gauge’ before the term was ever invented. Had the line still been in use today then European modern freight wagons including piggy-back lorry services could have operated over the line without any bridges having to be altered. If ever a railway line was ahead of its time, then this was it.

The Great Central Railway was absorbed into the London North Eastern Railway (L.N.E.R.) in 1923. The LNER was one of the big four railway companies. Later these big four were amalgamated into the new British Railways in 1947.

Killamarsh Station had two platforms with a timber building with a substantial canopy on each, a footbridge joined the two. The booking office was in the ‘up’ side of the line to the north of the station.

Killamarsh Station was renamed Killamarsh Central on 25 September 1950. At some stage both canopies were rebuilt and in the late 1950’s the building on the down platform was demolished and replaced by a waiting shelter.

At the south end of the station, water troughs were in position to enable express trains to pick up water before arriving at Sheffield Victoria station, this would save time at Sheffield before leacing for Manchester.

Several single lines were also in the vicinity of Killamarsh station, one would lead to the Flour Mill from Beighton Junction and another to the Tar Distillery near Rotherham Road, another single line went over the main road on Rotherham Road to Kiveton Park.

During the summer months special trains were advertised to Cleethorpes via Killamarsh Junction and Waleswood Curve, which is now part of the Rother Valley Country Park.

Killamarsh Central was a very busy route, nearly all the slow trains to Chesterfield Central and Nottingham Victoria were booked to stop at the station. Also express trains to London were quite frequent. There were also named express trains such as The Master Cutler, South Yorkshireman and the York to Bournemouth service.

It was also quite busy for freight trains as well, fully fitted trains from York to Woodford passed on a daily basis, fish trains from Grimsby ran via the Waleswood Curve into Killamarsh Central then headed towards Leicester Central, and coal trains ran to Annesley from the Mexborough area, also the local trip trains that dropped coal wagons off at different points for the coal merchants.

The station closed on 4 March 1963 when local services on the Great Central were withdrawn but continued to be used by some excursion trains until 6 May 1963. The station remained open for goods traffic until 12 June 1965 and a private siding remained in use after that date.

In 1976 the building was bought by Havenplan and used as an architectural emporium selling a large range of architectural memorabilia including many railway items, they also hired artifacts to film and TV companies.

The track through Killamarsh remained in use until February 1983 having been used up until that time for coal traffic ffrom Arkwright Colliery, although it wasn’t used after 1981 when a new spur onto the former Midland line was laid at Staveley. The track through Killamarsh was lifted in February 1983.

New housing was built to the north of station, partially on the trackbed and on the goods yard in 1989 although the Trans-Pennine Way was maintained through the site.

The trackbed now forms part of the Trans Penine Way.

Upperthorpe and Killamarsh Railway Station

The station was opened by the Lancashire, Derbyshire and East Coast Railway in March 1897 and closed in 1939.

The first station here had been opened by North Midland Railways in 1840 and was replaced by the Midland Railway in 1873 by a station that was renamed Killamarsh West.

The Lancashire, Derbyshire and East Coast Railway wished to extend into Sheffield using the Manchester, Sheffield and Lincolnshire Railway’s lines but was rebuffed, and instead joined the Midland’s line at Beighton Junction to join the Sheffield District Railway at Treeton Junction.

_________________________________________________________

KILLAMARSH FORGE

From Medieval times a Forge of sorts was situated on what was known as Mill Road, so called because a Corn Mill used the river for power, the river being the River Rother or to use its ancient name ‘Rudwhr” meaning Red Water due to the impregnation by iron-oxide picked up from the banks which must have contained deposits or iron ore.

The Steelmelters Arms in Netherthorpe Lane is reputed to be named after the workforce employed at the Forge.

The Forge, at first using the aforementioned iron ore which was reasonably accessible, was producing sickles, scythes and primitive plough-shares for the local inhabitants. In times of trouble they manufactured an array of weapons for example swords, spears, arrow-heads and a primitive type of armour.

This would be the sum total of the Forge’s capabilities in medieval Kynwoldsmaresc for many years. In fact it was centuries later in the 1700s that a person named William Cooper established an iron works in partnership with John Harrison to harness the power of the River Rother to drive giant water wheels to power the bellows required for the iron smelting process and also for any other item needing power.

It was in all probability that the name of the road was changed from Mill Road to the more familiar Forge Lane at this time.

The Forge was sold in its entirety to Joseph Butler in the 1800s. He developed a rolling mill and produced chains, shovels, spades and farming equipment. He is also credited with the invention of the container as we know it, wagon boxes would be lifted on to flat rail bogeys and lifted off at the destination.

The Forge changed hands many times in the 1800s.

The Forge suffered for many years by flooding, sometimes for as long as ten weeks at a time, which was not remedied until the river was re-aligned.

oooooooooo

The following article was written by John Jennings, a Killamarsh resident who worked at the Forge.

In 1824 Joseph Webster III co-owner of a wire drawing firm Websters took out a lease on the Forge. This was to enable the company to control the quality of the crucible steel made in the U.K. to rival the steel produced in Sweden. The addition of the melting capability at Killamarsh allied to their other U.K. melting forges enabled the firm to increase wire production at the Penn Mill, Wharmley, Birmingham, tenfold during the next 6 years, allowing the firm to compete with the German wire producers both in cost and quality.

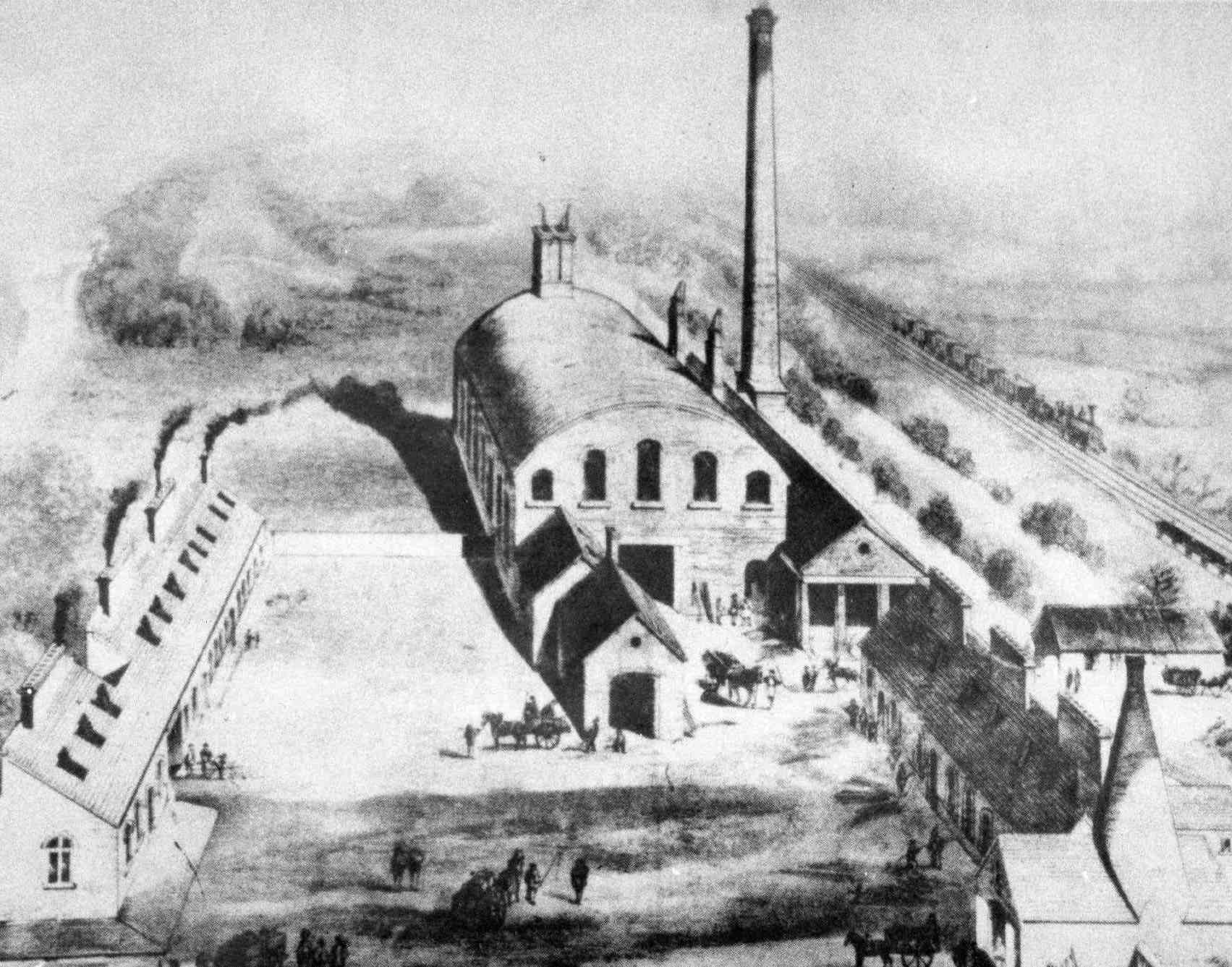

In the book The Iron Masters of Penns, the Forge is described as having a battery of crucibles, a cementation furnace and water operated tilt hammers

The image below shows how the Forge appeared during the 1800s. The image is also in the Iron Masters of Penns book.

The Forge was managed by John Bird, a very capable man, who instigated the melting of Huntsman crucible steel. This was done in lidded crucibles with charcoal added to the crucible. He also oversaw the commissioning of a hot rolling mill.

While on a stagecoach ride to the Head Office, Bird overheard two Sheffield men talking about the improvement to steel on the addition of manganese. On his return to Killamarsh he started experimenting with additions to the steel which enabled Websters to keep ahead of the market for twenty years.

In 1855 Joseph Webster III and James Horsfall signed an agreement to unite both families in the one firm.

Metal ingots 3/4” square x 36” long were the original product of the Forge. These were sent to Birmingham originally by barge then after the building of sidings on the Midland Railway by rail to Penn Station in Wharmley. These ingots had to be reheated and rolled into 1/4” rods which then went to be drawn into wire, after the addition of the hot rolling mill at Killamarsh the product delivered was a 28lb 1/4”rod.

John Bird died suddenly in 1839, and the management of the forge was taken on by the Richardson family, father George then son William until Webster and Horsfall ceased production there in 1887 due to a lapse in the lease.

The working week was 54 hours.

The weekly wages were:

Labourer 18/- (80p)/week

Furnaceman 25/- (£1.12)/week

Metal Rollers Wire Drawers could earn £2-£3 /week depending on production levels.

These figures were obtained from the book The Iron Masters of Penns by John Horsfall.

Webster & Horsfall touched the lives of workers in Killamarsh for 63 years, but it was 110 years old when it came to Killamarsh and is still in production in Birmingham in the year 2013. Not many firms can have been in production for the 293 years Webster and Horsfall has.

In the late 1890’s the site was owned by two firms Emmett & Co, a glassmaking firm, then owned by Gregory & Bramall who operated the rolling mill.

Ross & Co Foundry Ltd. bought the Forge in 1936 and used the existing crucible furnaces to produce Huntsman type steel. This continued until 1939 when Ross & Co invested in electric high frequency melting units. This enabled the company to produce millions of permanent magnet blanks during World War II.

The magnets produced by Ross’ during the war were blanks, just castings. They were sent to Marrison & Catherall’s factory at Fawcett Street, Sheffield to be machined and magnetised.

During the early fifties Marrison & Catherall decided to move from Sheffield to a greenfield site on Forge Lane, into a purpose built factory to be nearer to their main casting supplier.

This move took place in stages in late 1955 and early months of 1956. The laboratory was the last department to move, this took place on Cup Final day 5th May 1956. (Thanks to Muriel Beaumont a former laboratory technician at Marrison & Catherall for the information re the move).

At this time Ross and Co had started to concentrate mainly on steel fabrication with the foundry producing magnets for Marrison & Catherall.

In 1961 Ross & Co recruited a new salesman (Desmond Mawson who went on to become Managing Director of Ross & Catherall) who realised there was a new market for specialised alloys for the then expanding aerospace market. The company began to produce air melted bar stock. This was sold to Rolls Royce who recast the bar into blades which were used in Jet engines. As the tonnage of alloy needed increased, more room was needed in the foundry/fabrication shop for the production of moulds for the alloys. The company built a workshop to move the fabrication department into. This workshop is now the site of Massey truck bodies.

The work for the aerospace enabled Ross & Catherall to expand.

During the early sixties the management of Ross & Son’s and Marrison & Catherall decided to merge the two firms and change the trading name to Ross & Catherall.

This merger took place in 1967, and resulted in two divisions in the company, the Foundry Division and the Magnetic Material & Engineering Division.

The American jet engine makers realised that super alloys were needed for the hot end of jet engines and these could only be manufactured when melted under vacuum.

To keep pace with the U.S. engine makers Rolls Royce had to buy alloy from American bar stock manufacturers.

The board at Ross & Catherall took the decision to turn to vacuum melting as the way forward. A purpose built foundry was built this contained a 500Kg vacuum melting unit. This was commissioned in 1968 and enabled Ross’s to supply specialised alloys used in the production of blades in the hot end of jet engines. It also opened a market in car engine market for alloys for turbo chargers, cobalt alloys for replacement joints.

The 1970’s saw rapid expansion at the Forge Lane site. A new shop was built in 1971 to house a 2500Kg vacuum unit and all ancillary departments needed to service it.

Also in 1971 a new automated air melt foundry was built, number two air melt. The air melt furnace had a 1000Kg capacity and allowed the company to double its bar stock production. Number two air melt was further expanded in 1975 with the building of a 2000Kg furnace and a new casting system.

The original foundry was still producing magnets and was producing castings for heat treatment furnaces. 1975 saw more investment in the vacuum melting side of the company, the building housing the first 2500Kg was expanded and a second 2500Kg vacuum melting was installed. This furnace was commissioned in early 1976 making Ross & Catherall one of the largest producers of super alloy in the world. A new purpose built foundry for the production of magnets was built in 1976.

During this period of expansion the company bought an investment casting foundry on the Isle of Wight which it supplied with alloy, and a super alloy producer in Long Beach, California C.A.P.I.

The early 1980’s saw further investment in the vacuum melting with the building of a third 2500Kg vacuum unit. A new building was built as storage for alloy but it was tuned into a central weighing shop which serviced all the melting units on the site.

In 1983 the original foundry of the company, which was now only producing general castings in heat resistant materials, was deemed surplus to requirements. The existing orders were cast and the foundry closed, the staff incorporated in other departments.

Due to increasing use of electronics the magnet market ceased to be viable and the magnet finishing part of the site closed in 1995, the buildings being used as storage until they were demolished around 2009.

The company, which had been privately owned, was launched on the stock market in early 1990’s,

The small group of Ross & Catherall companies was taken over by Vickers plc in October 1989, Vickers paying £108.2 million.

With the late 1990’s came more investment, a new melting unit was planned Project 2000.

The old foundry was demolished and in its place was built a self contained melting unit with a 6000kg vacuum furnace with a conventional casting unit on one side and a continuous casting unit on the other, with its own finishing department in the same building.

There was a change of ownership in 1998 when Vickers ceased trading and the Ross and Catherall group was bought by Rolls Royce plc.

The Royal Bank of Scotland Investment group bought the Ross group in early 2001, they then bought Daniel Doncaster engineering and merged the two companies.

The new group of companies was then sold on in 2006 to the investment organisation Dubai International Capital.

John Jennings

_________________________________________________________

THE HISTORY OF MINING IN KILLAMARSH

WESTTHORPE COLLIERY

(National Coal Board – North Derbyshire Area)

Steam Winding

1923-1984

Click on to the small box for recording of the winding engine.

History

Westthorpe Colliery came into existence in 1923 when a single shaft was sunk to the Deep Soft seam by a local mining company, J. and G. Wells Lttd. The company already owned two other mines in the area, Holbrook and Norwood Collieries, and it was to Holbrook that the Westthorpe shaft was linked, acting as an intake airway for a section of the Holbrook workings.

In later years these roles were reversed when, after Holbrook Colliery had ceased production in 1944, its shaft continued in use to provide ventilation to the Westthorpe workings.

The first sod was cut on the Westthorpe site on St. Patrick’s Day, 17th March 1923. Prior to this there had been three Holbrook shafts sunk in the arly 1890s, and two for the Norwood Colliery in 1866, all to access coal in the Eckington area.

Between the sinking date and the time of nationalization in 1947 the Westthorpe shaft had three different owners. In 1941 it was taken over from the Well Company by the Tinsley Park Colliery Company who retained it for only three years before ownership passed to United Steel Companies Ltd. At about this time the Wells Company itself became part of the Rother Vale Collieries Group and remained so until nationalization.

The depth of the Deep Soft seam to which the Westthorpe shaft was sunk was 137 metres. Production started in the seam in 1928 and for the next 23 years the pit won its entire output from that seam only. From the outset extraction was by the longwall method of mining.

In 1949 work started on the drivage of two drifts at gradients of 1 in 4.5 from the Deep Soft pit bottom into the Thorncliffe seam. As they progressed the drifts passed through a section of the Parkgate seam and a decision was taken that this intermediate leaf of coal should also be worked.

Production from the Parkgate started in 1951. However, the seam’s potential was limited by faulting and washouts and it was replaced by the Thorncliffe seam two years later. From this time output from the Thorncliffe and the Deep Soft seams continued for almost 20 years –until 1971 in the Deep Soft and 1972 in the Thorncliffe.

When the reserves in these two teams neared exhaustion, drifts into the Chavery seam were started in 1968. This seam was developed in 1970 and its first face brought into service in March 1971. During the following12 months the Thorncliffe and Deep Soft seams were phased out leaving the Chavery as Westthorpe’s only production seam for the remainder of its life.

Regrettably the quality of the Chavery was never the same as that of the earlier seams and this was a factor which weighed heavily when the eventual closure decision was taken.

In the same year that the cross-measure drifts were started (1949), the pithead baths, sufficient to accommodate 1,252 men, and a medical centre were also constructed. This was a period in which the comforts of the employees were being improved quite considerably. For example, in the previous year the pit’s first manriding system was installed in the Deep Soft seam. In 1950 a Meco-Moore cutter loader was introduced to a Deep Soft face and while this might not be regarded as a ‘comfort’ it certainly made the lot of the Westthorpe miner a lot easier.

For 11 years after coal production had ceased at the Holbrook mine, a Holbrook shaft was used to extract air from the Westthorpe workings. In 1953, however, worked started on the construction of a 1 in 3 drift from Westthorpe pit bottom to the surface. The drift was completed in February 1955 and equipped with an electric ventilating fan which did away with the need for the Holbrook shaft as a return airway. Nevertheless the shaft was still retained in use, submersible pumps installed at the bottom helping to keep the Westthorpe workings clear of water. It continues to provide a pumping service for the still active mines to the east.

At the time of the suface drift construction new headgear was also erected.

EXPLOSION

There was an unusually dramatic incident at the colliery on a bleak wintery March night in 1964 – an occurrence which resulted in the death of one of the the London Underworld’s top gelignite experts.

The London based criminal, known as ‘The Expert’ because of his special knowledge of gelignite, was trying to blast is way into the Westthorpe explosives store, his attempts being covered by a driving blizzard. Unfortunately for him his plan went wrong and all the explosives in the store, about 700 kilos, were blown up.

The brick and concrete store was totally demolished and the would-be thief killed by the blast.

Fortunately, no-one else was injured although debris was flung more than 450 metres away, crashing through roofs and windows of nearby houses. In some cases the damage was so severe that the occupants had to be temporarily evacuated.

Westthorpe’s ground-mounted steam winding engine was manufactured and installed in 1924 by a Lincoln Company, Robey & Co. Ltd. The cost of the installation was £3,330, plus an extra £70 ‘for the services of a skilled man to supervise the erection.’

Throughout its life the engine has been used to wind two single deck cages through the shaft.

One of the advantages of the winder is that it is a very compact piece of equipment and it generates a great deal of power for its small size. It is one of only three steam winders now left in the North Derbyshire coalfield, with the exception of the now closed Pleasley Colliery, where the other two steam winders are located, all the local mines have converted to electric winding gear.

For the technically minded, the Westthorpe winder has two double acting cylinders which build up a working steam pressure of 145 psi. The winding drum is a semi-conical type controlled by twin vertical post type, spring hydraulic brakes.

WESTTHOPRE COLLIERY MANAGERS

1927 – 1943 H. Kendall

1943 – 1947 E. Thompson

1947 – 1960 G. Walker

1960 – 1962 P. J. Griffiths

1962 – 1966 H. Glasby

1966 – 1967 A. Wheeler

1967 – 1970 J. Rodgers

1970 – 1972 C. A. Heeley

1972 – 1975 J. White

1975 – 1983 K. P. Hees

1983 – closure A. Vardy

The following article appeared in COAL The Magazine of the Mining Industry in Volume Nine – Number One – in May 1955. Price 4d. (Courtesy of Anthony Broome).

PORTRAIT OF WESTTHORPE COLLIERY

Story by Leonard Halls : Portraits by Hayward Smead

One of the most northerly of East Midland pits, Westthorpe Colliery is keeping over 1,250 miners busier than they have been since the pit’s extraction method was changed in 1951.

During that year Westthorpe ceased stint-working in favour of continuous (or ‘composite’) mining, in which coal is extracted by both the morning and the afternoon shifts, who also do ripping, cutting and packing.

Rapid extraction means rapid advance and development, and a saving, too, in back-repair work.

“By this system”, says manager George Walker (in charge eight years now and formerly under-manager for 12 years), “one of our faces in the Four Feet seam is being extended by 16 yards a week and by 750 yards a year. The coal is water-infused during getting. Roof support includes the use of 5,000 Dowty props. Output is about 11,000 tons a week, OMS 33 cwts. The eventual increase hoped for is 15,000 tons weekly.” (The pit’s present record stands at 12,197 tons in a week of October, 1952). “Recent additional men-and-materials haulage improvements – with other re-organisation – should raise OMS to 35 cwts. None of our men would go back to stint working now – we’ve put an end to that monotony.”

Continuous mining is also of advantage to the older men in the 46 man face teams. If the more strenuous jobs become a little too much for them, they can still play a useful, if less strenuous, part in the team. This is especially valuable in a colliery like Westthorpe, where more than 100 men are between 60 and 70.

Among the development is a new loading point installed May 1954, dealing with 300 tons an hour on one-ton tubs (instead of 13 cwt tubs). When present man-riding by 10 eight-seater Metro-Vick cars drawn by endless rope was extended (by early March, it was hoped), the men would be riding nearer their working units.

A 530-yard ventilation drift from the Flockton seam has just been completed, after 13 months work. Rising 1-in-3, the drift is supported by 14 ft. by 12 ft arches set at every yard. (The arches were lifted from the supply point and transported to pithead by the ‘Matbro’ mechanical lifter, which was also used to convey the new one-ton tubs across the colliery yard to the shaft).

At the top of the drift a new fan – made by James Howden Ltd., of Scotland, to a Dutch design believed to be the only one of its type in the coalfields – is of 425 h.p., with a capacity of 250,000 cu.ft.

On the surface, new headgear erection completed during the August holidays was not allowed to impede production; the new headgear was built around the old (smaller) one which it replaced.

Westthorpe has an extensive plan for the better disposal of its pit-dirt. Instead of adding to the colliery tip, the debris will be used to fill a shallow valley near the colliery. The dirt will be carried along an extension of the screen conveyor to a 400-ton capacity bunker recently built by Simon-Carves Ltd.

From the bunker the dirt will be taken as required in ten-ton dumper trucks which will deposit it in the valley and level and pack.

Sinking of foundations for the steel pylons, on which the screen conveyor will be extended to the bunker, was completed by April. Whilst this work was being done, the good top-soil of the valley was being lifted and set aside in preparation for the dumping of the debris. When all levelling has been completed, the top-soil will be replaced.

Colliery development at Westthorpe, excluding the valley dumping scheme, is expected to cost £250,000.

The pit’s St John’s Ambulance Division, 80 strong, is the largest in an area well-known for its active ambulance work. The colliery manager is superintendent of the men’s section; superintendent of the 50 cadets is Renishaw time office member, Superintendent J. Walpole. Instructor (for 30 years) is Westthorpe safety officer George Parkin.

The colliery sports club has soccer, cricket, angling, golfing, bowls and pigeon sections.

Each Westthorpe man makes a voluntary payment of 6d. when need arises to enable a single payment of £4 to be made to each sick or injured miner away from work for ten weeks. Since 1947, when this scheme started, £1,356 has been paid out.

By voluntary levy Westthorpe men also send some 300 old miners and their wives to Rhyl miners’ holiday camp, and some 600 to the similar camp at Skegness, at reduced prices.

For their paraplegics, Westthorpe men make a weekly stoppage from pay of 1d. to provide a fortnight’s holiday for each patient. Last year also each paraplegic’s wife was given a washing-machine.

Westthorpe miners are keen, too, on their band: the Killamarsh Welfare Prize Band, of 22 miner-players, including a 10-man dance orchestra.

With its vigour in development, its strong interest in welfare and sport, this pit is a well-balanced unit. It is not surprising that since 1943 there has been no stoppage through disputes – which have always been settled at pit level by discussion between management and men.

MANAGER George Walker (pictured below) has been in charge at Westthorpe eight years. For 12 years he was under-manager, but afterwards spent some years at Oxcroft and Markham Collieries. He began his mining career at Holbrook pit as a white-washer. For five years he attended night and Saturday afternoon mining instruction classes at Sheffield University; during this period he became a deputy. He sat for and gained his under-manager’s and manager’s certificates in 1921.

UNDER-MANAGER George Bradshaw (pictured below) began his mining career at 14 as an Ireland pit pony driver. Later he went through the hand-got period; he became shot-firer, deputy and overman, then on to Ireland’s first mechanised stall, working as a cutter for 12 years. Later he spent five years at Glapwell. In February this year he completed five years as Westthorpe’s Under-Manager.

TRAINING OFFICER: lumberman, farmer, four-horse timber-sled driver (in Canada for three years) Westthorpe Training Officer Tommy Green (pictured below) started in mining at Holbrook, went on to Norwood and Kiveton Park and then, in 1929, went to Canada, settling in Memphremagos (Indian for ‘Beautiful Waters’), in Quebec Provence. Back home in 1932 he was roadlayer at Holbrook (under his present manager), then temporary under-manager, and later deputy (with his father, 54 years in pit and now retired at 76). In 1934 Tom came to Westthorpe as deputy, later overman, then training officer. He has been colliery rescue-team captain 10 years and team member 19 years. He is also an Area CD instructor.

N.U.M. SECRETARY George Daykin first came to Westthorpe at the age of 34. He has held his present office since 1944. He began at the pits at 14 at Holbrook, then went on to Norwood and afterwards came to Westthorpe where he is a back repairer.

N.U.M. TREASURER William Taylor (pictured below) came to Westthorpe in 1945. Five years later he was elected Lodge treasurer. He began in mining at Holbrook and later was a member of that pit’s C.C. He is a back repairer.

LODGE PRESIDENT: Beginning in the pits at 14 at Norwood Colliery, James H. Calpin, Westthorpe’s Lodge president, came to the colliery from Renishaw Park in 1944. He has been president since 1945. He is also workmen’s inspector, back repairer and secretary of the colliery golf club.

BATHS SUPERINTENDENT: Stage presentation is one of the spare-time interests of Baths Superintendent Ken King (pictured below), in charge at Westthorpe baths four years (he was previously baths attendant at Kiveton Park, and before that a ripper). He began at 14 at Kiveton Park. He was in charge of artistes’ make-up at the Sherwood pageant in 1954.

MEDICAL CENTRE NURSE: State registered nurse Albert Reynolds (pictured below) has been in day-to-day charge of Westthorpe Colliery medical centre since last March. He received his training in six years’ service at Sheffield Royal Infirmary. Three medical attendants, one for each shift, assist him.

OVERMAN: Starting at Norwood (since closed) at 14, Hugh Staton (pictured below) went on to Beighton at 15½, spending seven years in stone drifts with his father (lately retired at 70). From Beighton he went to Orgreave, in 1942 became a deputy, and came to Westthorpe in 1946. In 1949 he was made an Overman, and is that grade’s representative on the C.C.

HEAD ELECTRICIAN: Unit Head Electrician Cyril Wilson (pictured below) started work at 14 as apprentice electrician at Holbrook. He studied at evening classes at Chesterfield Technical College from 1933 to 1940 and obtained his ordinary and higher national certificates in electrical engineering. He was appointed Head Electrician at Westthorpe in 1949.

ASSISTANT ENGINEWRIGHT: Starting work at 13 at Beighton Colliery on the surface, Westthorpe’s Assistant Enginewright C. Furness (pictured below) became an assistant apprentice blacksmith at 16. He transferred to Westthorpe Colliery, where later he was appointed foreman fitter and in 1947 Assistant Enginewright.

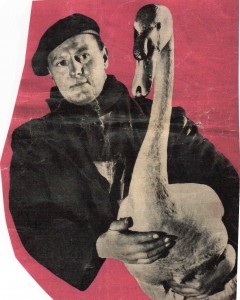

SURFACE ELECTRICIAN AND PIT MASCOT: Beginning at the Colliery as a surface worker at 14 years, Westthorpe Surface Electrician L. Palmer – pictured with ‘Charley’ the swan, pet of the pit – joined HM Forces in 1939, serving in the Reconnaissance Corps he was demobbed at the end of the war with the rank of Sergeant. Entered the electrical department in 1947 as a cable repairer and later became Surface Electrician.

‘Charley Boy’ has been the pet of the pit ever since he settled on the colliery reservoir three years ago with an injured wing. He has the freedom of the pit yard but accepts special attention only from Surface Electrician L. Palmer.

COLLIERY CONSULTATIVE COMMITTEE:

Seated (left to right) L Baker (Face worker), A. Cauldwell (N.U.M. Rep), G. Daykin (Lodge Secretary), H. Warwick (underground haulage), G. Taylor (underground contractor), H. Sewell (Secretary), G. Walker (Manager), G. Bradshaw (Under-Manager), Standing (left to right) A. Williams (surface worker), W. Taylor (Lodge Treasurer), R. Adams (Tradesman), H. Staton (NACODS representative), C. Furness (Assistant Enginewright), C. Wilson (Unit Electrician in Charge).

_________________________________________________________

THE MINERS’ STRIKE

In January 1985 the Killamarsh Women’s Action group undertook a thirty-mile tred around seven North Derbyshire pits. The following was published in the Derbyshire Times on 9 March 1990.

Derbyshire women were among the first to organise support of the striking miners. A group set up by Chesterfield Labour Party to support Tony Benn’s election decided to stick together and back the strike, and withing days of the strike starting they had organised a soup run to miners on the picket lines. And, under the banner ‘They shall not starve’ they organised canteens and collection points for food and fuel.

Tom Vallins of Chesterfield Labour Party said the work done by the women was one of the most memorable aspects of the strike. “The women were marvellous,” he said. “They were organising the food collections and speaking in support of the stike. It was amazing how they did it.”

Those who did not know the mining communities were astonished by the women’s valour but the women were the first to admit that they often surprised themselves.

Toni Bennett from Chesterfield Women’s Action Group said: “It made women far more aware of their own capabilities.”

Gordon Butler, secretary of Derbyshire NUM, described the sense of family tradition in the villages which the women were determinted to preserve. “Women had always stood strong in the mining communities. You saw this in the pit disasters when they supported the widows and comforted the men,” he said. “There had always been an inherent family atmosphere and when the women saw the threat of the break-up of their families they reacted instinctively.”

PIT CLOSURE

In line with a decision taken jointly in November 1983 by the National Coal Board and representatives of all the mining unions Westthorpe Colliery, at Killamarsh, officially closed on 31st March 1984. It had ceased to produce coal seven weeks earlier.

The decision had been taken in order to protect as fully as possible all coal industry employees within the northern sector of the NCB’s North Derbyshire Area. Apart from those men who elected to take early retirement or voluntary redundancy, all the Westthorpe men were guaranteed jobs at other local pits.

_________________________________________________________

HIGH MOOR COLLIERY

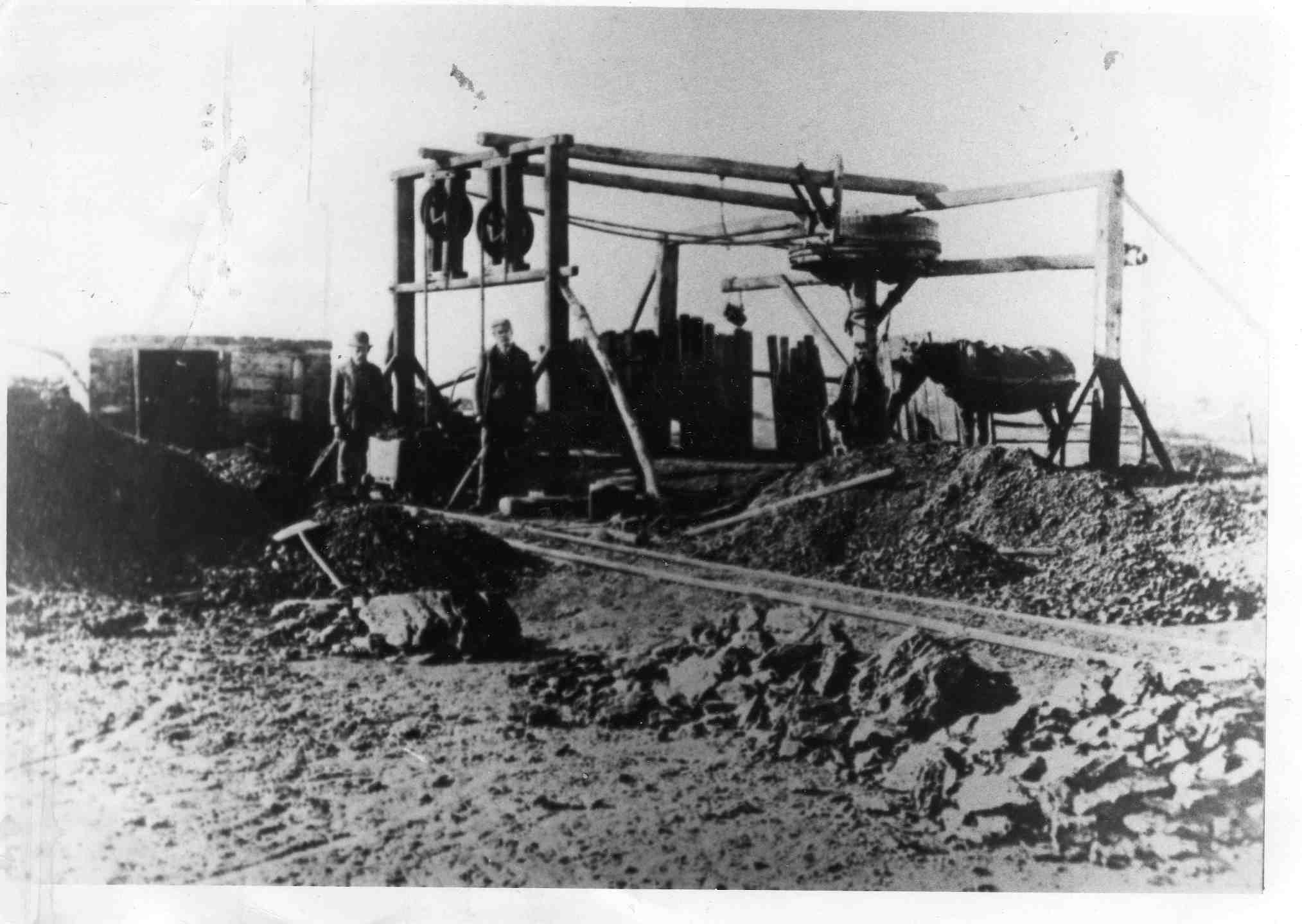

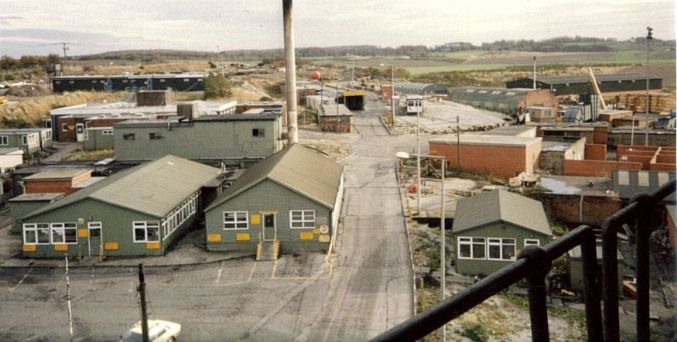

Above and below – photographs of the old High Moor Colliery at Killamarsh, which operated between 1831 and 1909.

The top photo shows the bowler-hatted, Mr Greensmith, standing at the top of the shaft, from which coal was raised in a large bucket by means of a horse-operated Jenny Wheel.

The photograph below shows the remains of the pit chimney in a later period.

Photographs courtesy of Mr Ken Wain from his book The Coal Mining Industry of Sheffield and North East Derbyshire.

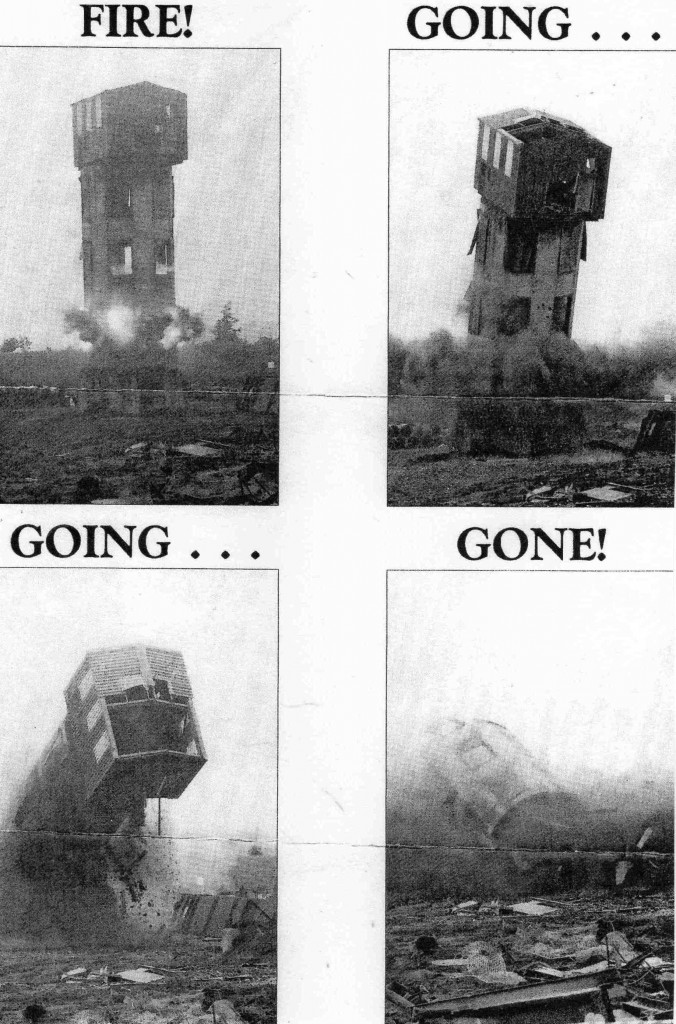

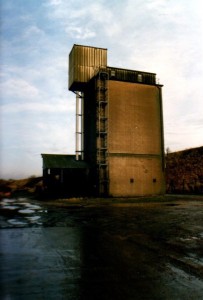

On 1st June 1994, the disused R.O.M. cascade tower at High Moor Colliery was demolished.

The tower, out of use for two years, had long been a prominent landmark.

Undermanager, Niall Betts, took a sequence of photographs of the event, including the ones above.

The engineers employed were Robinson and Birdsell.

(NB – for the enthusiast: Camera – Nikon F301; Lens – Tamron 80-120 200m, Film – Kodacolour Gold 200.

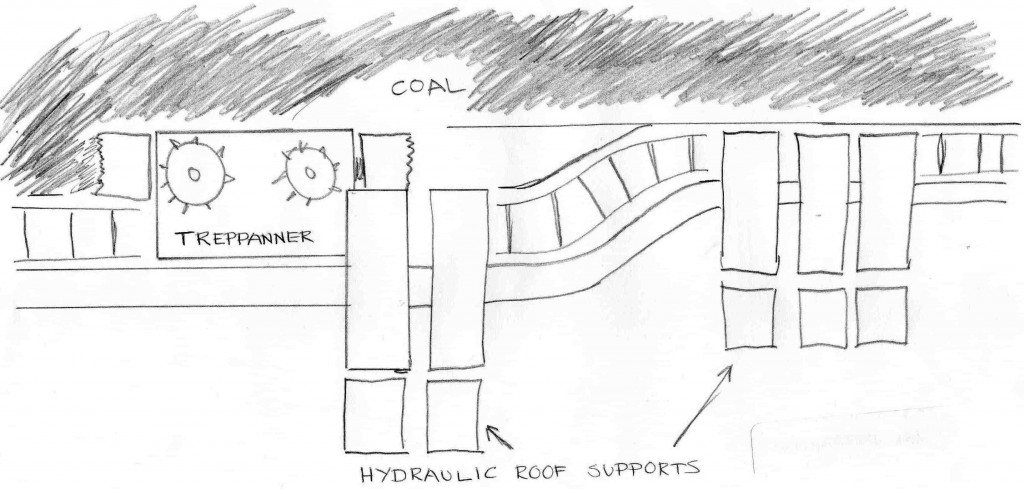

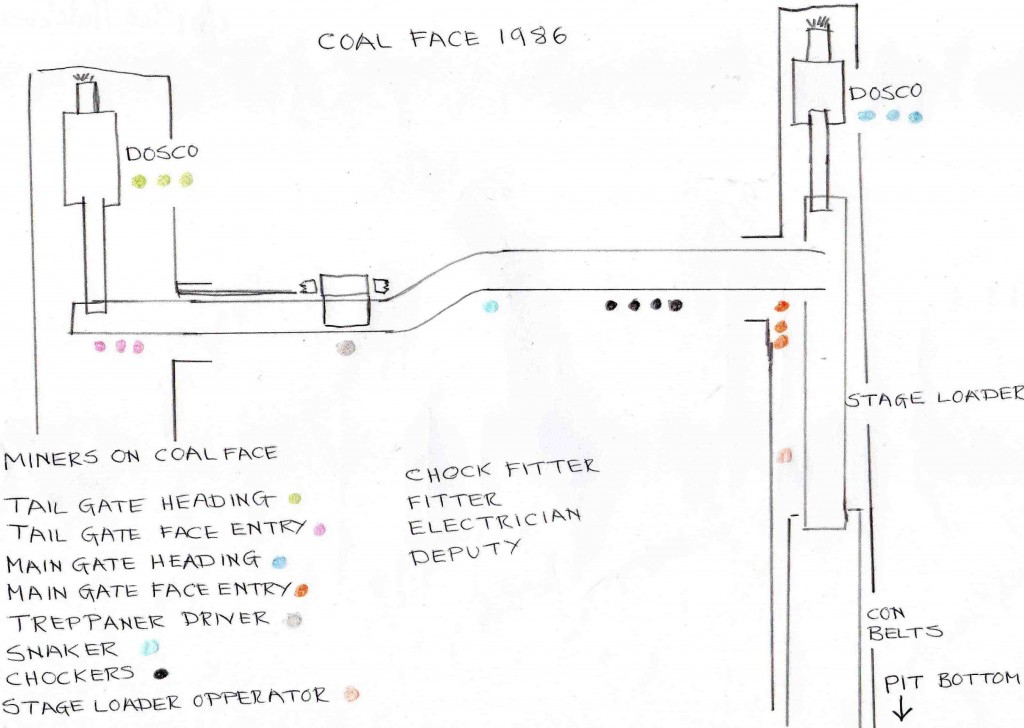

Plans of the Mine at High Moor Colliery

Thank you to Peter Hutchinson for the plans which he has sketched of the mine at High Moor Colliery.

_________________________________________________________

NORWOOD COLLIERY

1865 – 1943

The shaft was sunk in July 1865.

The seam was reached on 1st February 1867.

The pit closed in 1943.

The Wheel of Norwood Colliery behind the Angel Inn at Norwood.

The following article appeared in The Colliery Guardian on 9th February 1867.

On Saturday last, a very substantial supper was provided for the workmen at the above Colliery by the Sheepbridge Coal and Iron Company, in commemoration of having reached coal there, at a depth of about 170 yards.

Upwards of 80 sat down, and a very pleasant and agreeable evening was spent by all present.

Amongst the company were the Rev. E.H. Smith, incumbent of Killamarsh and several Killamarsh gentlemen, Mr Longbottom, Manager at the Colliery, was called to the chair, and after the cloth was drawn, briefly opened the proceedings by referring to the remarkable and almost unexampled success that has attended the sinking of these shafts, the coal having been reached without a single accident of any kind.

He considered this as a matter for congratulations and thankfulness, as they had had difficulties to contend with in the earlier part in the sinking which required great skil and judgement from the management, and also great endurance and exertion to overcome. He paid a high tribute to the master sinker, Mr. Wain, for the tact and energy he had shown in the undertaking and congratulated all on the amicable way they had worked together and on the good feeling that had lasted throughout.

The Chairman then proposed “Continued success to the Norwood Colliery and prosperity to the Sheepbridge Coal and Iron Company”, which was drunk with great enthusiasm.

Mr. Smith next proposed the health of William Fowler, Esq., of the Whittington Hall Company, which was rapturously drunk with musical honours and with three times three cheers and one over, and the same honours for Mrs Fowler and family.

Mr. Birbeck and Sheepbridge staff received a similar ovation, also Mr. Longbottom, Manager at Norwood. Other toasts were drunk, and the remainder of the evening was spent in songs, etc., most of them given in really excellent style.

Mr. Simonite, Angel Inn, Killamarsh, was the caterer, and great credit is due to him for the way in which the supper was served.

The Norwood Colliery is sunk for the purpose of obtaining hard coal. The seam is nearly five feet thick and of excellent quality and will no doubt prove a very valuable property to the Sheepbridge Coal and Iron Company.

Very powerful machinery is already erected, and when the Colliery becomes developed it is expected the daily output will be from 600 -700 tons.

The Midland Company are now constructing a railway to the Colliery, the set for which was obtained last session.

_________________________________________________________

KILLAMARSH CHURCHES

The following is an extract from A KILLAMARSH CHRONICLE Killamarsh Comes of Age 1770 – 1900 by Aileen and Vincent Hopkinson (Copyright 1994 Aileen Hopkinson).

NEW LIFE FOR THE ANCIENT CHURCH

The parish church which is the oldest building in the village might well have a book of its own. Ancient as it is, not all that can be seen today is as it was when our village review begins.

It is commonly believed when people speak about the old days that churches were full of honest, God-fearing folk who loved and cared for the churches which they had inherited from the past. Sadly, this is not borne out by fact, nor indeed was Killamarsh any different in that respect from many other places throughout the country. Where a noble or affluent gentry family lived in a village, the church might be well-maintained if only as a repository for tombs and family memorials, but in places like Killamarsh which never had such a family resident, matters were quite different. Ordinary people who worked long hours for small and often irregular wages, had enough on their minds. The church was for them, as it still is for some, a place where babies were baptised, couples wed and funeral services were held. Lip service was paid to the worship of God in attendance at the customary festivals of Christmas and Easter.

This is not the place to deal with the organisation and financing of the church, dependent as it was on a system of customary offerings, tithes and taxes though a fuller study would demand that. The fact remains that upkeep of the church as a building was not seen as a priority. In earlier centuries the church had been the main centre of not only religious activity but also local festivities with the churchyard used for grazing cattle, holding fairs etc. and its porch especially the place where marriage arrangements were made, deeds signed, debts paid and various other affairs conducted. Had familiarity bred contempt?

THE CHURCH BEFORE 1840

R. R. Rawlins in ‘The Churches and Chapels in the County of Derby’ has left us our earliest 19th century reference as to the state of the church. In 1821 he saw the church still with the overall dimensions it had had since the building of the tower, believed to have been in the 15th century. The length was 59’ 7”, with tower added 72’ 9”. The chancel was under 11’ long, the nave taken up with wooden box-pews and (presumably) the tombs known to have been there from an earlier period. He found the box-pews especially towards the belfry in a falling position. Across the nave ran a gallery cutting out light from the west window in the tower. At that time in the 1820s music in the church was provided by a band which probably used the gallery. From the scanty surviving churchwardens’ accounts we know that in 1830 a bass was bought for £3. The leader of the band before the first organ was installed by Parson Smith in 1845 was John Watson of Upperthorpe who was a carrier.

Attempts were made to remedy matters, or instance in 1832 when the churchwardens made some efforts to attend to the broken pews and floor but came up against indifference. Wealthier people rented pews and occupation of a pew often went with the holding of property. Iron gates were purchased so that grazing animals could be shout out of the church and churchyard. There was just not the financial input to allow real restoration.

——————————————————————————————————————-

THE PARISH CHURCH OF ST GILES

St Giles (pictured above)

Saint Giles was a Greek Christian hermit saint from Athens, whose legend is centered in Provence and Septimania. The tomb in the abbey Giles was said to have founded in Saint-Gilles-du-Gard became a pilgrimage and a stop on the road that led from Arles to Santiago de Compestela, the pilgrim way of St James. He is one of the Fourteen Holy Helpers.

He was born c650 and died c710. His patronage is against plague, for a good confession and for cripples, beggars and blacksmiths.

His feast day is the 1st of September

The Rectors of Killamarsh since its independence from Eckington in 1843:

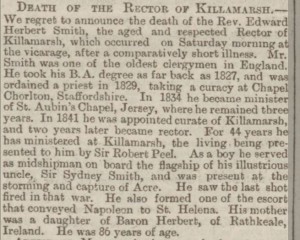

Edward H. Smith

The following press cutting was published in the Nottingham Evening Post on 22nd August 1887. (Courtesy of Joan Salmon)

Francis J. Metcalfe (pictured below)

J. Septimus Powell

Norton John Raper

John Milner

Gilbert Stanley (Chris) Cheetham

Peter D. Peterkin

Clive Hilton (pictured below)

John F. Statham

Roy J. Bradshaw

Helen Guest

Rev Helen Guest has been in post as Priest in Charge since June 2007, together with her husband Michael Guest, an Associate Priest.

Miss Eva Shirtcliffe (pictured below) was organist at St Giles Church for many years. She will also be very fondly remembered as being the Secretary at Killamarsh Endowed School for many years.

St Giles Church is a Grade II listed building.

Killamarsh is mentioned in the Domesday Book and was called Chinewoldmaresc, which means a marshy settlement belonging to Chinewold. There is no mention of a chuch at this time but there is evidence that this was a Christian community well before the Norman Conquest, as we have an earlier stone preaching cross just outside the present building.

The present church was started in the 12th century, probably on the site of an earlier wooden building. Originally, it was an oblong building with a flat lead roof. The tower was added in the 15th century and various alterations were made in the 19th century. These included the rebuilding of the chancel in the 1840s, a new high pitched roof and an addition of the north aisle and vestry, leaving us with the building we have today.

Killamarsh has only been an independent Parish since 1843. Prior to this, it was a parochial chapelry to the Parish of Eckington. One of our former incumbents, Revd Francis Metcalfe, left a remarkable history of life in this mining community. He wrote a book called “Colliers and I. It was published in 1903 and gives a fascinating account of life in the Parish and the social conditions at that time.

_________________________________________________________

KILLAMARSH SCHOOLS

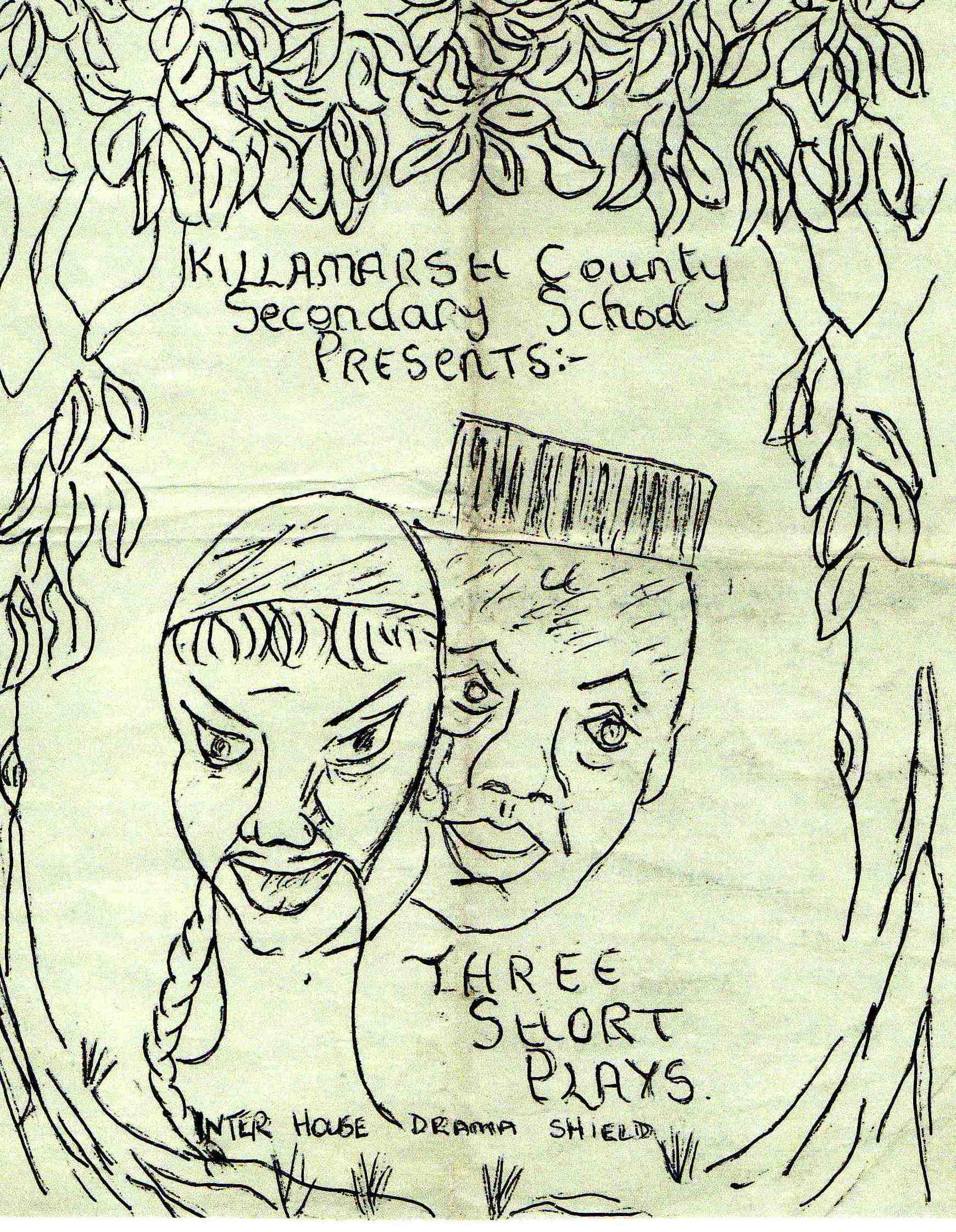

Killamarsh County Secondary School

The following is a programme for three plays held at Killamarsh County Secondary School for the Inter House Drama Shield circa 1961. The three houses, Haddon, Chatsworth and Melbourne each put on a play. The programme is courtesy of Margaret Slack (nee Batterham).

PLAY NO. 1

MELBOURNE HOUSE PRESENTS

UNCLE MIDNIGHT

Characters

JANET Janis Baldwin

MONA Angela Watts

MRS. BUSBY Brenda Limb

DESMOND Alan Smedley

VICKY Ursula Barber

Scene A Victorian boarding-house at the seaside

Time About 1900

PLAY NO. 2

HADDON HOUSE PRESENTS

ROAST PIG ON A WILLOW PATTERN PLATE

Characters

HERALD Peter Dodd

BANG HON, Executioner Roy Unwin

OM BONG PONG Charles Fisher

CHAMBERLAIN John Whitfield

GUARDS Robert Weakford and Geoffrey Webster

SING HI Keith Hilton

SING LO Philip Robins

HI TEE Philip Burgess

BO BO Philip Slatter

VILLAGERS Geoffrey Webster, Stephen Wombwell, Philip Robins

Scene 1 A Chinese Garden

Scene 11 The Courtyard of HI TEE’S House

PLAY NO. 3

CHATSWORTH HOUSE PRESENTS

BIRDS OF A FEATHER

A Welsh Wayside Comedy by J.O. Francis

Characters

TOM TINKER Hazel Mullins

DAFT DICKY Brian Sparkes

JENKINS, the Keeper Peter Garfitt

THE BISHOP OF MID-WALES David Weston

A POLICEMAN David Baumforth

Scene A roadside in rural Wales

Time The action takes place at 10 o’clock at night

oo – O – oo

Once more I wish to express my personal thanks to all those whose hard work and enthusiasm have made possible the public presentation of these plays.

This year we have our new stage lighting, plus a new stage extension on which Mr Stoakes and the boys have worked for many hours.

The players, and the producers, offer their efforts for your appreciation. I hope that you will accept them with approval.

R. H. REID, Headmaster

Producers:

Melbourne Mr. J.V. Thornton

Haddon Mr B. Martin

Chatsworth Mr T. Ellin

Scenery: Mrs J. Arblaster, Mr B Stoakes, Mr E. Lound assisted by children

Lighting/Stage Managers: Mr P. Hurst and Mr P. Reynolds

Costumes: Mrs L. Riley, Mrs S Berry, Mrs V. Rogers, Miss J Hart (and of course helped by many children).

_________________________________________________________

THE FLOUR MILL

Glover’s Mill

Page Feeds

(Thank you to David Page for the information and photographs)

Above: Note the office block and weigh-bridge in this 1986 picture – the office can also be seen to the left in the old Glover’s Mill picture.

The first Page Feeds ‘open day’ was on the 20th of September 1977 after new manufacturing facilities had been installed.

Above: The Provender Mill when Page Feeds of Tadcaster owned Valley Mill (picture date 1986)

Below: The Silo at Page Feeds (picture date 1986)

The Mill production was mainly geared towards manufacturing broiler feeds for delivery in bulk.

Below: A ‘Page Feeds’ bulk feed delivery truck of the period.

Hi Peak Feeds

_________________________________________________________

THE SKATING TRAGEDY IN KILLAMARSH

Sunday 28th November 1915

Six Drowned

(Articles about the tragedy appeared in national newspapers including The Telegraph, the Daily Mirror and the Scotsman)

A terrible accident involving the death of six young people occurred on the Chesterfield Canal at Churchtown, Killamarsh on 28th November 1915.

The Canal which was no longer used for traffic had been frozen over for some days, and in certain parts large numbers of children were indulging in sliding and skating. There was an unusually large number of young people on the ice, and the numbers apparently proved more than the ice could bear, when suddenly there was an alarming cracking sound.

Before anyone had time to realise what was happening, the six victims, who were close together were plunged into the water, which was approximately nine feet deep.

Miss Nellie Foster of Churchtown, Killamarsh, stated that she was in a field by the side of the Canal near Church Lane at 2.45 pm and noticed two young women and two young men arm in arm walking or sliding on the ice. Suddenly there was an ominous cracking, followed by screams and the four young people were struggling in the water.

Miss Foster screamed for help, and a young man, Wilfred Sargeson, a Miner of Long Lane, Killamarsh, who was a short distance away, ran to the Canal bank at the point where the accident had taken place. He promptly got on to the ice to give assistance, and managed to grab one of the young men, but the ice gave way and he dropped into the water.

There were other men on the spot by this time – Benjamin Milner (brother of Harry Milner), George Watson (father of six year old Mary Watson who was drowned), Joe Kelk, two men named Jones and Watts, and several others. In the absence of ladders or planks, rescue work was practically impossible for the ice broke away as soon as anyone approached the hole through which the victims had fallen. Fortunately, a rope was at last produced, and with this Mr Sargeson was rescued. He was taken home in an exhausted condition and it was felt necessary to call in Dr Saunders of Wales.

At this point no one in the water was visible, but Police Constable Tinder was summoned and at once commenced dragging operations.

Other people also searched the canal with drags and six bodies were recovered within the hour.

Dr Adams of Killamarsh was present during the operations but could only pronounce the bodies dead as they were brought to the bank.

The fatalities all took place in one part of the Canal within a radius of three or four yards.

The victims were:

Fred Northridge (aged 18), Pony Driver, son of Fred Northridge, Miner of Kirkcroft Square, Killamarsh.

Harry Milner (aged 18), Pony Driver, son of Elizabeth Milner, widow of Kirkcroft Square, Killamarsh.

Annie Sedgewick, (aged 12) daughter of Sarah Sedgewick, Kirkcroft Square, Killamarsh.

Mary Elizabeth Watson (aged 6), daughter of George Watson, Miner of Kirkcroft Square, Killamarsh.

Alice Read (aged 21), Pottery Hand, of No. 1 Dock Wall, Boythorpe, Chesterfield.

Mary Ann Ramskill (aged 18), Pottery Hand, of No. 6 Spa Lane, Chesterfield.

|

IN LOVING MEMORY OF MARY ELIZABETH

The beloved Child or George and Emma Watson

Who was Drowned in the Canal at Killamarsh November 28th 1915

Aged 6 Years ___________

And was Interred at Killamarsh Church, December 2nd __________ Short was our little darling’s stay She came but as a guest Just tasted life, and flew away, To her eternal rest.

|

|

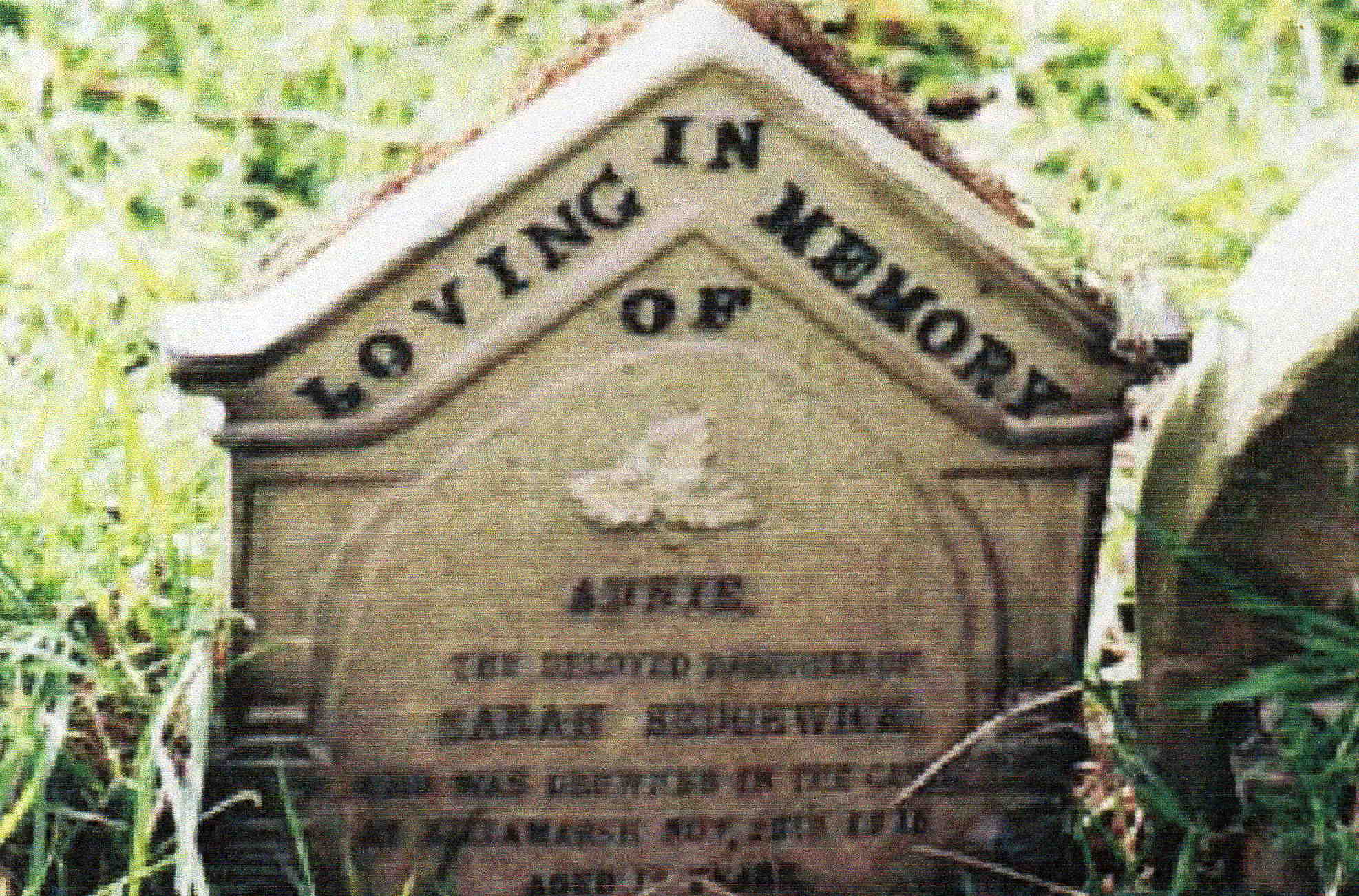

IN LOVING MEMORY OF ANNIE

The beloved Daughter of Sarah Sedgewick

Who was Drowned in the Canal at Killamarsh November 28th 1915

Aged 12 Years ___________

And was Interred at Killamarsh, December 2nd __________ She sleeps in Jesus, life’s bath is o’er, Sin, sorrow or pain shall effect her no more; The valley is past, the victory won, And all that is wearying, past and done.

|

|

IN LOVING MEMORY OF HARRY

The beloved Son of Elizabeth Milner,

Who was Drowned in the Canal at Killamarsh November 28th 1915

Aged 18 Years ___________

And was Interred at Killamarsh, December 2nd __________ How we miss him and how sadly, Heaven and earth alone can tell, We have lost him, Heaven has found him, Jesus hath done all things well.

|

|

IN LOVING MEMORY OF MARY ANN

The beloved Daughter of Arthur and Fanny Ramskill

Who was Drowned in the Canal at Killamarsh November 28th 1915

Aged 18 Years ___________

And was Interred at Killamarsh, December 2nd __________ What though in lonely grief we sigh, For one we loved no longer nigh, Submissive, we must still reply Thy will be done.

|

Miss Read was engaged to be married to Tom Northridge, brother of Fred Northridge, the banns having been read out for the second time at Killamarsh the same morning.

The disaster cast a gloom over the village, and the war had to take second place as a general topic of conversation.

For some time after the occurrence there was a wide spread fear that the tragedy was even more serious than six fold. When the dragging operation resulted in the recovery of the sixth body, it was rumoured among the hundreds of people who lined the Canal bank that a seventh person was missing. The Police and civilians continued to drag the Canal for some time, but as the afternoon moved on without anyone else being reported missing, the search was discontinued shortly before 5.00 pm.

The inquest into the accident was held on the afternoon of Tuesday 30th November 1915, at the Congregational School, Killamarsh. It was stated that there was a stream running into the Canal near the spot where the ice gave way, and it is thought this fact coupled with the weight of a group of people at one particular place explained the cause of the ice giving way. It appeared that the victims were sliding on the ice in a kind of procession, Harry Milner linked arm in arm with Mary Ann Ramskill, and one of the two young women from Chesterfield taking the lead. Miss Ramskill was visiting Killamarsh with a friend, Alice Reid who came second in line. Behind them holding a part of their clothing came Annie Sedgewick and little Mary Watson. The sliders were all laughing and joking when Harry Milner slipped and fell heavily in a sitting position. The other members of the party tripped over him and their combined weight proved more than the ice could bear, and all six disappeared into the water, their screams being described as agonising.

There were a number of children on other parts of the ice and they at once got to the Canal bank.

According to reports the Canal had been frozen over for some days and the ice had supported an unusually large number of young people before the accident occurred.

This would suggest that for the Canal to be frozen over the weather must have been sub-zero for a number of days, and this was towards the end of November.

____________________________________________________________________________

ROTHER VALLEY COUNTRY PARK

Rother Valley County Park lies to the north of the village. This was created in the early 1980s as part of the restoration works following open cast mining of the area. Originally managed by a joint board of Sheffield MBC, Rotherham MBC, South Yorkshire MCC and Derbyshire CC, the park is now wholly managed by Rotherham. The scheme created a series of ponds and lakes, with the surrounding area landscaped to form a nature reserve and recreation areas, with facilities for water sports. The River Rother flows from the West and passes through the centre of the park. The site falls on the border between South Yorkshire and Derbyshire.

___________________________________________________________________________

KILLAMARSH SHOPS

SHOPS IN KILLAMARSH IN THE EARLY 1930s

With thanks to Mrs Dorothy Bower and Mrs Joan Booth who walked around Killamarsh in their minds and gave us a list of the many shops we had in Killamarsh in their childhood.

STATION ROAD

Beginning at the top of the road:

Dyers Farm – Milkman

Mrs Burdett – General Store. Rented Caravans

Emmaline Bright – Sweet Shop

STEELMELTERS LANE (NETHERMOOR LANE)

Mrs Cunningham – Sweets etc.

SHEFFIELD ROAD TO THE MIDLAND PUB

Mr Swift – Piano and Violin lessons

Susanna Green – General Store

Killamarsh Fire Station

SHEFFIELD ROAD UP TO NORWOOD

Mrs Chiltern – Ladies Shop

Mrs Walker – Sweet Shop

Mrs Nichols – Sweet Shop

Mallenders – Draperery – men and women

Mallenders – Fruit Shop

Baumforth and Garfitt – Electrical Goods

Oscar Godber – Sweet Shop

Macey Snowling – Hairdressers

Salt Factory

Crofts – Fish and Chips

Marshalls – Groceries

Windles – Butchers

Mr Iggs – Chimney Sweep

Fox’s – Beer-off and Grocery

Morris’s – Sweets and oddments

Sadlers – Hairdresser

Sadlers – General Store

Dixons – Newspapers and sweets

Walkers – Fish and Chips

DYKE SIDE

Heals – Grocery

Batty’s – Fire Wood and General

Gascoigne – Funeral Director

NORWOOD

Healeys – Fish and Chips

Cordy’s – Groceries (later to become a Post Office)

ROTHERHAM ROAD

Mullins – Sweets, General Goods

Mr Shimwell – Cobler

Mrs Carr – Wool and Cotton

HIGH MOOR

Godbers – General Store

CO-OP – General Store (George Knight, Manager)

Stones – Anything they could sell.

Connie Weston – Groceries and cigarettes

Batty’s – Sweets etc.

MANOR ROAD (Bottom of)

Bartholomews – General Store (later became Co-op then Tom Marsh)

GREEN LANE

Halls – Sweets etc.

Mortons – West End

Greens Farm – Milk deliveries with horse and cart up to 1955

NAGS HEAD

– Miliners Shop

HIGH STREET

Wally Walker – Groceries

Mrs Furnace – Ice cream and cigarettes

Mrs Wards – Chip Shop

Mrs Baines – Groceries

Renee Cawkwell – Ladies fashions

ASHLEY LANE

Atkins – Firewood

Mrs Rivington – Pop and crisps

Mr Rivington – Hairdresser – worked in garden shed

Crown Yard – Fish from Grimsby – once a week

Mrs Rivington – Cottage by the Church. Sold yeast.

BUNKERS HILL

Mrs Green – Hat Shop and Dresses

Ben Harding – Sweets

May Snowling – Fish and Chips

CHURCH LANE

Frank Green

Mr Stones – Milk

CHURCH TOWN

Keatons – Beer Off

Mr Windle – Gents Outfitters

Butchers – near ? house

Smiths – Electrical bits and pieces. Charged accumulators used for radio and wireless.

Betting Shop

Draketts – Shoe Shop

Nellie Newton – Tins and sweets

Morris (alias Annie Calliss) – General Foodstuffs

Cordys – Fish and Chip Shop

Mrs Furnace – Second Hand Shop

BOTTOM OF BRIDGE STREET

Naylors – Chemist

Batty’s – Shoe Shop

Mrs Green – Fancy Goods and Petrol

Liedigs – Butchers

Co-op – Butchers

Mrs Cullen – Bakery

Fords – Fruit Shop

Mrs Curzon – Fish and Chips

Baines – Butchers

Sam Bates – Photography

Wains – Sweet Shop

Woods – Butchers

Mr Tags – Fruit and flowers

Mr Burnham – Choirmaster and Bandmaster, Newsagents. Daughter played the Organ the Cinema

Co-op – Mens Outfitters, Carpets etc

Above Co-op Hall – Used for functions, weddings etc

Westminster Bank – Run by Mr Silvers

Stevens – Sweet Shop

Johnsons – Wallpaper. One half of the shop became the first Killamarsh Library in 1953

Bramhalls – Post Office

Dr Lipps – Surgery (Prior Dr Adams, Sheffield Road on opposite side of road)

Stones – Sweet Shop

Widowiss – Sweet Shop

Co-op – Grocery

Co-op – Bakers (all produce baked in Killamarsh)

Co-op – Ladies Shop

Windles – Butchers

Johnsons – Greengrocers

Sarah Burnham – Hairdresser

Newhams – Newsagents

Baumforth & Garfitt – Electrical

Windle – Men’s Outfitter

Hunters (became Farrands) – General Store

Mrs Warwick – Her front room was used twice a week by Mr Reed the Dentist. Well remembered is the horse hair sofa you had to wait your turn on!

HUTCHBYS CORNER

Frittons – Grocery and Beer Off (during the war belonged to the Co-op)

Mr Bailey – Blacksmith

Fords Garage – Petrol etc

Mission Rooms – Meeting Hall

MISCELLANEOUS

Lizzie Taylor – Had the task of laying-out the deceased people in the village.

_________________________________________________________

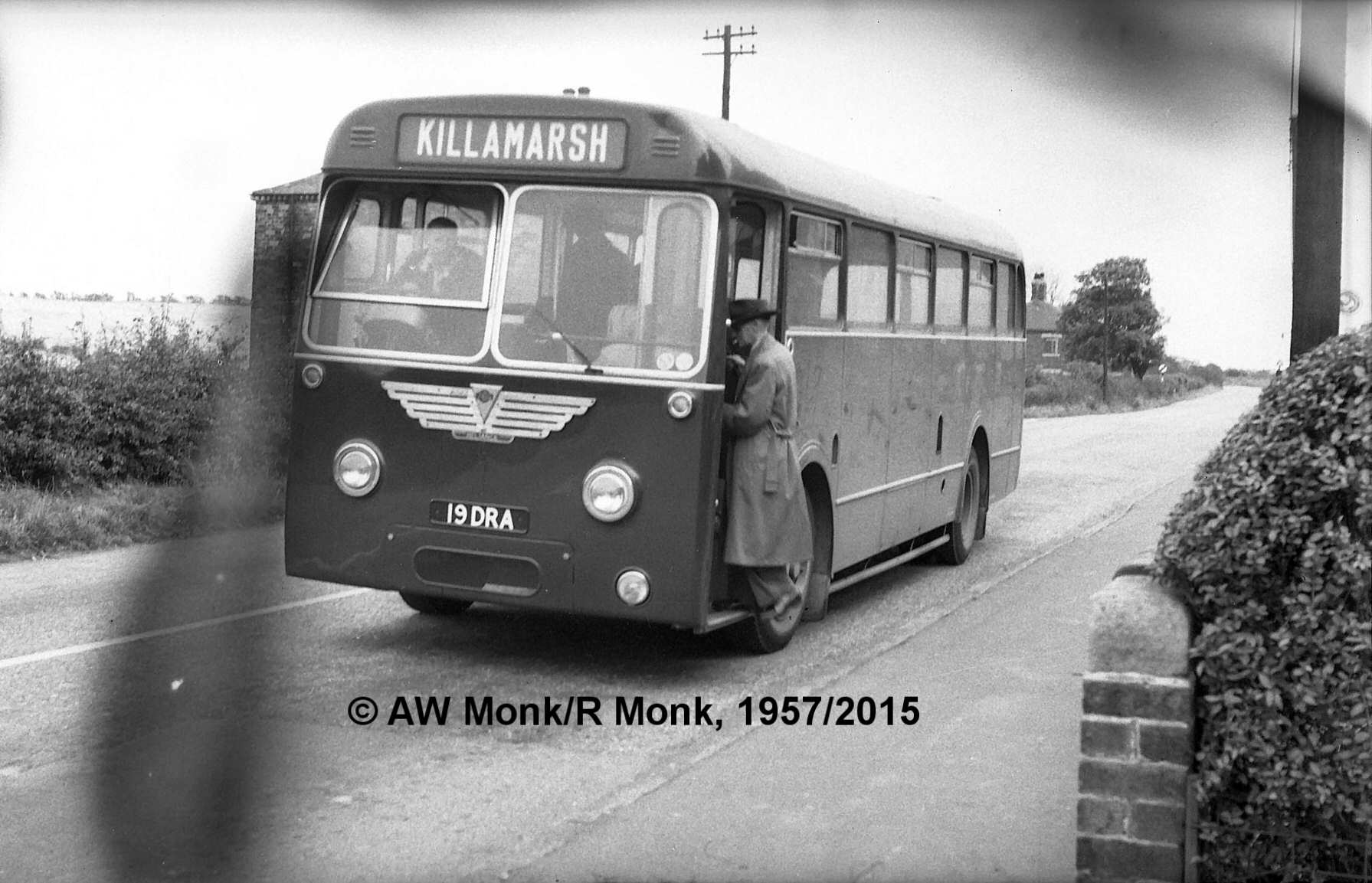

BOOTH AND FISHER BUSES

Many Killamarsh people will remember the Booth and Fisher Buses which were our main source of public transport for many years.

There were two main routes – High Moor to Sheffield and Beighton to Worksop.

Photograph courtesy of Roger Monk

Nellie Louder – Clippy on Booth and Fisher buses

Below: Booth and Fisher bus tickets – courtesy of Roger Monk